Making the wood surface smooth will provide a flawless appearance after painting. If not done, wood tends to have lumps and bumps that are not pleasing to the eyes. To achieve a smooth surface, you need to use grit sandpaper.

There are several sizes and shapes of sandpaper. The size of the grit particles in this substance determines its numerical rating. The rougher the sandpaper is, the lower the grit number indicates. And the finer the sandpaper is, the higher the grit number. In this article, we will discuss the different grits sandpaper, their importance, and some alternatives without them at hand.

The Different Grits of Sandpaper

As mentioned, there are various sizes and shapes of sandpaper. Getting the right sandpaper with the right grit will help you do the job efficiently. Choosing the right grit is more important if you need to work on wood.

40-80 Grit Sandpaper

It is the one that is used when sanding or removing stock quickly. If you use a belt sander for sanding the edge of a sticking door, then coarse sandpaper like this one is what you need.

If the paint also has a primer, this sandpaper is perfect. Using a coarse sandpaper is always better than using a paint stripper. The reason is that the previous can make the job more recent. You don’t have to worry about any mess, and it will also require less taping.

100-150 Grit Sandpaper

It is also known as a medium grit sandpaper and is the most commonly used starting point in any project. They can be used in sanding unfinished wood and removing old varnish.

180-220 Grit Sandpaper

It is one of the finer grits you can find in the market. This sandpaper removes scratches left by coarser grits on unfinished wood. This grit is also used in lightly sanding in between coats of paint.

320 to 400 Grit Sandpaper

It is used for light sanding in between coats of finish. They are also being used to sand metal and other hard surfaces.

Choosing Grit Material

While the density of the sandpaper grit contributes to the effectiveness of wood sanding, it is also crucial to understand that the type of abrasive material also plays the same role. Some grit grain work better with materials that are smooth and sand-like.

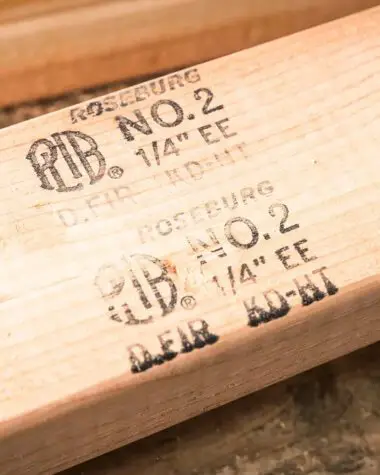

Thus, it’s a good idea to know what grit to look for before shopping because most manufacturers indicate the kind of material best suited for sanding on their product labels.

Aluminum oxide

Aluminum oxide works well for all kinds of hardwoods, sanding and polishing different kinds of metal, including bronze and alloy steel.

Emery

Emery sandpaper is a type of natural grain that is most frequently used to polish and/or remove rust from steel and other metals. For sanding wood, its particles’ edges may be too sharp.

Flint

Flint is a tough natural grain that works well for removing surface products like old paint or varnish.

Garnet

Garnet is a natural grain, but it wears down relatively rapidly when used to sand metal since it is a little softer than flint or emery. It works best for finely sanding wood.

Silicon carbide

It is the most resilient synthetic abrasive. Various materials can be effectively sanded with silicon carbide, including plastic, metal, hardwoods, and softwoods.

Zirconia alumina

This grit is long-lasting and well-suited for grinding away burrs on metal and for an initial sanding of rough wood. Zirconia alumina can make the grit particles sharper when used to sand metal, reducing the need for frequent sandpaper replacements.

What Grit Sandpaper to Remove Paint from Wood

The amount of paint you want to remove from the word surface will be the basis for the coarseness of the sandpaper you should use. If the job at hand only involves a thin layer of paint, then sanding it all together and making the grits is a thing that you can do.

You can also choose to use a liquid paint remover to get the job done. It would be best to remember that grit is usually associated with the sandpaper’s roughness and strength. It would help if you remember that as the grades get higher, the motor and gentler the sandpaper will be.

What is the Importance of Sanding

Sanding is the one that will make sure that the surface that you are painting will be free from any imperfections. This is true, especially when you are working on wood. Wood tends to have some lumps and bumps, and that is why making the surface smooth will guarantee that you will have great results after painting.

You will need to use various grits of sandpaper mentioned above, depending on the surface you are working on. Using the right grit will guarantee a smooth surface. If you find any large rough spots on the surface of the wood, then coarse sandpaper is what you need to use.

Once the major rough surface has been removed, you can then gradually move to finer grits to achieve that smooth surface. Once you can achieve a smooth surface, see that you will remove any dust. A tack cloth, especially in smaller wooden items, is handy in removing any dust particles on the surface.

Alternatives To Sandpaper

Sandpaper is the ideal tool to use when sanding wood. But what if you don’t have some on hand? We listed five alternatives to sandpaper and the method to use them.

Method 1. Walnut Shells

Take some Walnut Shells and rub them over the wood surface. This way, you can make sure that the surface is polished. After that, you can use a piece of cloth or leather to rub the surface.

The result will be a wooden surface that seems like it’s been treated with sandpaper. Not only does this method polish the wood, but it also results in an astonishingly sandpapered surface.

Method 2. Sand

Take some sand and sprinkle it over the wood surface you want to treat with sandpaper. Use a piece of leather or some hard cloth to rub the surface. This will work like sandpaper. The best thing about this method is that it is one of the few cheap methods to sandpaper a wooden surface.

Method 3. Wood Shaving

This method is even cheaper than using sand. If you don’t have any sand, you can collect some wood shavings.

Once you get the wood shavings, you have to filter them. In other words, you must check for anything hard that might be inside that pile of wood shavings. If you don’t check, you might end up damaging your wooden furniture or panel that you are sandpapering.

Method 4. Corn Cobs

Corn cubs are another material that can be used to smoothen wood. Get some corn cubs and rub them over the wooden surface. That way, you will get a nice smooth wooden surface.

However, you will have to clean up a lot as this method makes a lot of mess. If you are working in a workshop, you must take the remaining material and put it away. As its food material, it can also attract ants and other insects. Make sure you clean the workshop or the room you are working in thoroughly.

Method 5. Pumice

Many professionals prefer Pumice instead of sandpaper because Pumice results in a near-perfect, smoothed, polished surface. It is also often available in different grids. However, it is a bit expensive. Therefore, if you have a low budget, you should avoid it. Alternatively, you can get a Rottenstone.

Conclusion

Once you get enough knowledge about wood, you will find solutions to certain problems, like making wood surfaces smooth. Furthermore, choosing the right grit sandpaper to work on is crucial. Familiarizing yourself with the concept of grit sandpaper for wood will ensure you get the best result.