Have you ever made a model airplane? You may have wondered how amazingly light the wood used to make it, right? This is balsa wood and is known as one of the lightest and the most efficient wood to use for making toys and other light wooden products.

Balsa is extremely easy to work with but if you don’t know how to cut it then you might end up wasting precious material. This guide will help you cut balsa wood for hobby or building use.

Cutting balsa wood the easy way

Balsa is soft and light but it is actually a hardwood. The balsa tree hails from South American countries like Brazil, Bolivia, and Mexico.

It has broad leaves instead of needles like conifers and in nature, it is a very hard tree, almost invincible from strong winds and sunlight because of its huge moisture content.

But once it is cut, dried and processed, balsa wood becomes the perfect model airplane building material.

Because of the softness of balsa, it becomes an easy material for crafting, models, lightweight traveling cases, fishing lures and also as musical instrument because of its exceptional tonal qualities.

The techniques used to cut balsa vary from cutting larger pieces with power equipment and cutting thinner pieces by hand using sharp knives.

The best kind of blade to use

Keep in mind, the only kind of blade and knife to use is the sharpest. Sharp blades are recommended for cutting balsa thicker than about 1/4 inch. You may also use hardened steel blades if these are new, or have recently been sharpened. Another good option is carbide-tipped blades because these hold a sharp edge longer compared to using high-speed steel blades.

You must use hollow ground cabinetmaker’s blades to make the best cuts on balsa. You must never use ripped blades. This can result in chipping and splintering and this is no good for making model crafts and toys.

Hollow-ground or cabinetmaker’s blades have a square, flat teeth. On the other hand, ripped blades by jagged, pointed teeth that can tip back and forth alternately.

Thin and thick balsa

Bandsaw and scroll saw blades are described by the tooth count. To use on ¼ inch thin balsa, blades with 12 to 14 teeth per inch teeth is the ideal saw blade. For thick balsa, you must use a band saw with lower tooth counts of about 10 for balsa thicker than 1/2 inch. If the balsa you are working on starts to burn, smoke or resist cutting then you might have to use a saw with a lower tooth count.

Things you will need

- Balsa wood

- Bandsaw

- Scroll saw

- Craft knife

Instructions

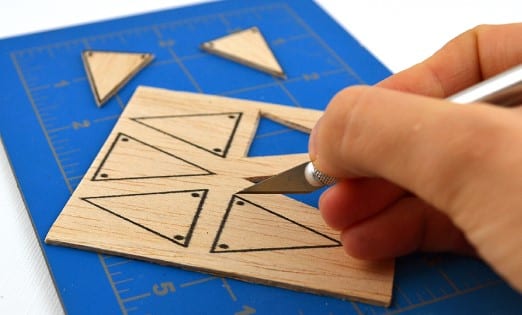

Making cuts on 1/4-inch or thinner balsa is done mostly by hand using a craft knife or utility knife. Here are the steps:

1) Establish the lines

Source: http://fallfordiy.com/blog/2017/07/26/diy-balsa-wood-plant-stand/

You can use a template or use a pencil to draw a pattern on the wood. Draw on a 1/8 or 1/4-inch-thick balsa wood.

2) Remember proper knife position

Source: http://woodpaintbetsugashi.blogspot.com/2017/04/balsa-wood-paint.html

To cut properly, you must hold the knife correctly. Hold the tip of the knife at 45 degrees to the wood. Apply very light pressure to the knife. Create the first cut perpendicular to the grain only.

Move the knife on the pattern, start making all other initial cuts perpendicular to the grain of the wood.

3) Join the lines

Source: http://sp.thescrapmaster.com/2012/01/stamping-on-balsa-wood.html

Start to cut the remaining parallel lines, to join up the other perpendicular cuts. The initial cut should be no deeper than 1/32 inch.

Repeat the steps as many times as needed until the knife goes through the pattern and releases the knife.

The Janka Hardness Scale

Balsa is the softest and lightest commercially available wood. This ranks only 90 to 100 on the Janka Hardness Scale. This is a scale for wood density worldwide. You can use this scale to easily find out the hardness of the wood you are working on. Red oak is a common domestic hardwood and ranks 1290 on the Janka scale.

Conclusion

Cutting delicate, soft and light balsa takes special tools and a lot of patience. If you want to become a better model plane builder then you need to learn how to work with balsa especially cutting it without breaking it.