To make wood from trees useful as a building material, it must undergo various processes like the ones in manufacturing. What’s more interesting is that while woods undergo these processes, they create residues that still have value. These residuals from the manufacturing process are either recycled back into the process, used as fuel to dry wood or produce steam, or transformed into other goods like landscaping mulch or animal bedding.

Why Use Wood Processing Residuals?

The use of wood processing residues has steadily increased due to the rising demand for and shortage of wood, as well as cost savings and resource efficiency needs. In 2010, approximately 83.4 million tons of primary wood processing residues were produced, of which 98 percent were recovered, burned, or otherwise unusable.

Remains from wood processing can be utilized directly to generate heat and energy or indirectly to create bio-based goods like chars or pellets. The production of other goods such as particleboard, nonstructural panels, and animal bedding uses around 85% of recoverable coarse wood processing residues and 42% percent of fine residue.

Common Wood Manufacturing Residuals

With all the information about wood residues and their importance, here is the list of the most common wood manufacturing residues.

Bark

The bark is the outermost layer of a tree, accounting for about 9 to 15 percent of a log’s volume. It is frequently used for mulching and as a fuel source. Because bark transfers heat less readily than wood, it is also utilized in insulation boards and fiberboard, two building components.

Due to the high cost of shipping, storage, and bulk of the material, bark’s chemical use is still in its early phases. Only a small number of isolated, pure organic compounds from the bark have been produced on a big scale.

Sawdust

The wood particles left over after a log has been sawed into lumber are known as sawdust. Most of the time, sawdust comes from green wood and is largely uniform in size and shape when it is first created. The term “wood flour” is also frequently used to describe sawdust, indicating that the particles can pass through a 20-mesh gauge screen.

Unfortunately, there aren’t many uses for green sawdust. For its minimal use, green sawdust can be used for smoking meats and residential heating in specialized sawdust furnaces, though this is rare. After being dried, sawdust can be used to produce power, heat, and oil through the processes of gasification, combustion, and pyrolysis.

Wood Shavings

Wood shavings are extracted when the wood is shaped or planed using machinery like planers and milling machines. They may come in different sizes and shapes. Wood shavings build up well into enormous heaps and are soft. Wood shaving piles act as a softer surface.

Typically, air-dried or kiln-dried wood is used to make shavings. In gardening, wood shavings are used as mulch. When shavings are sprinkled around plants and shrubs, they conserve moisture, keep weeds and grass at bay, and cool the plant roots. Other uses of wood shavings include:

- Animal Husbandry

- Mushroom Production

- Food Processing

- Building Products

- Environmental Protection

- Wood Flour Products

Wood Chips

Wood chips are typically produced as a byproduct of wood processing, when small branches, offcuts, and other debris are fed into a wood chipper to compact tree waste. They can make chips if the larger wood pieces have no other uses.

Wood chips are frequently used as a ground cover. It will help retain soil and prevent weeds from growing through. They are frequently used in playgrounds because the grass isn’t likely to stay long, and gravel would be very hard if someone fell. Some gardeners spread the chips out amongst their plants as mulch to prevent grass and weeds and to give the garden a smooth, uniform appearance.

Wood Pulp

During the papermaking process, wood pulp is obtained by decomposing wood chips or recycled paper. The main components used to manufacture wood pulp include trees, cotton, and other plant products. It is safe to use and consume this byproduct of wood. Additionally, it is exceedingly easy and cheap to make wood pulp.

Wood Flour

Wood flour is a product of the drying and subsequent pulverization of wood chips into a fine powder. Although other types of wood are occasionally utilized, maple or pine are the primary materials used to make this product. Wood flour resembles and feels much like sawdust, but it usually has a finer texture. It can be mixed with epoxy resin to create putty, which is helpful in various construction jobs.

Wood Pellets

Wood pellets are produced from dried wood scraps, ideally with as little bark as possible. Modern stoves and furnaces for burning pellets have automatic feed and control modules since pellets are a preferred type of wood fuel. So, burning pellets is possible with little effort. Additionally, they are frequently economical, and the combustion units are dependable. Usually, there is little ash, especially if using too much bark when making pellets, which is avoided.

Wood Waste As Source Of Biomass

People have used wood for lighting, heating, and cooking for thousands of years. Until the middle of the 1800s, the United States and the rest of the world relied primarily on wood waste for energy. About 2.1% of the nation’s total energy consumption in 2021 came from wood and wood waste, including bark, sawdust, wood chips, wood trash, and by-products from paper mills.

Biomass In The Industrial Sector

Manufacturers of paper and wood products are the biggest industrial users in which most wood waste is used. They produce steam and electricity from waste from paper and lumber mills, which saves money by lowering the number of other fuels and electricity they need to buy to run their facilities. About 5.2% of industrial end-use and 4.2% of overall industrial energy consumption in 2021 were made of wood and wood waste.

Biomass In The Residential Sector

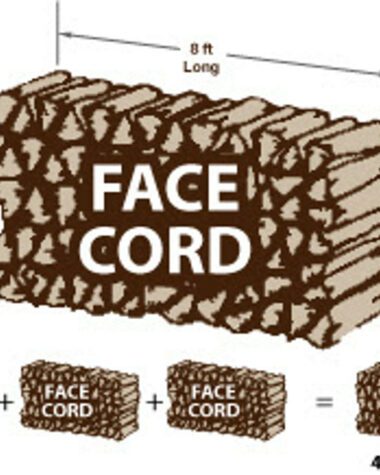

Meanwhile, the residential sector is the second-largest user of wood for energy in the United States. In America, wood is used to heat homes as pellets in pellet stoves and as cord of wood in fireplaces and other wood-burning equipment.

In 2021, wood energy accounted for roughly 2.2% of all residential energy consumption and 4.0% of the sector’s end-use energy. About 10.8 million homes, or 8.8% of all U.S. households, utilized wood as an energy source (mostly for space heating) in 2020. Of these, 2.2 million used wood as their primary source of space heating.

Biomass In The Electric Power Sector

Numerous power plants primarily burn wood to produce electricity in the electric power sector, and some coal-burning power plants burn wood chips and coal to cut down on sulfur dioxide emissions. The primary purpose of wood consumption in the business sector is heating.

Key Takeaways

As you explore the wonders of information and facts about wood, you become more knowledgeable about its nature and what it can do for humans. Much like the above information only proves that wood is purposeful in any form. After some manufacturing procedures, people might think of it as dust or tiny particles, but it is still useful. With human’s capability to create something useful for living, wood becomes a primary tool to make it come to life.